Since the beginning of the full-scale military operations in Ukraine, the U.S. authorities have been regularly imposing all sorts of sanctions against Russian legal and natural persons, and over this time the sanctions agenda has already become a routine thing in the eyes of many Russians. Therefore, yet another package of blocking sanctions, recently announced by the Office of Foreign Assets Control (OFAC) of the U.S. Department of the Treasury, went virtually unnoticed by the expert community. This is unfortunate since the package is notable: not only because it broadly introduces secondary sanctions against individuals and organisations from third countries involved in circumventing the restrictive measures and supplying electronics to Russia, but also because it ultimately places virtually the entire Russian automotive industry under the toughest type of U.S. sanctions, depriving it of any prospects for growth.

AvtoVAZ is next

The latest Russian carmaker to be placed on the U.S. Specially Designated Nationals and Blocked Persons List (SDN List) was AvtoVAZ. The impact of this type of sanctions goes far beyond the territory of the United States and does not only prohibit individuals in the U.S. jurisdiction from entering into any economic transactions with the sanctioned person, but also puts companies from third countries at risk of facing secondary sanctions, as well as administrative and even criminal prosecution. Accordingly, any contracts for the supply of automotive components and parts for AvtoVAZ, or any agreements on partnership and implementation of joint projects with this company, a priori entail serious risks of the counterparty falling under U.S. sanctions, regardless of its country of origin.

For many years, the business of AvtoVAZ remained unprofitable until the company reached profitability thanks to the efforts of managers of the Renault-Nissan alliance, which became a major shareholder in 2013. AvtoVAZ generated 386 million roubles of net profit in 2019, with 742 million roubles in 2020, and 1,497 million roubles in 2021. In recent years, four Lada models (Priora, Kalina, Granta and Largus) and two Lada Niva SUV models (Travel and Legend), as well as models of three other brands: Renault (Sandero and Logan), Nissan (Almera) and Datsun (On-do, Mi-do), were produced at AvtoVAZ facilities in Togliatti. The Lada Vesta and Xray models, as well as the Nissan Sentra, were produced in Izhevsk. The average annual total production volume at these sites in the 2010s totalled approx. 500 thousand cars. Renault’s strategic plan was to merge Russian Lada and Romanian Dacia into a single business unit aimed at strengthening production synergies between the brands, increasing the level of localisation, updating the range of models and raising production volumes on the common platform to 1 million cars per year.

However, the war in Ukraine ruined these plans: the Renault-Nissan alliance sold its shares in AvtoVAZ for a very low price and withdrew from the Russian market, causing the largest drop in production at the company’s facilities and making 2022 the worst year in its history (sales of Lada cars plummeted by 46% year-on-year). Nevertheless, a few months later, the company was able to resume the production of its most localised models, i.e. the simplified versions of Granta and Niva (these cars lack the ABS anti-lock braking systems and airbags), and ended the year with a net profit of 207m roubles. Moreover, in 2023, AvtoVAZ became the owner of the former Nissan plant in St. Petersburg, for which it generously paid EUR 1, and soon began assembling Lada cars there.

At the same time, the plans to relaunch production as well as the business strategy for the further development of AvtoVAZ, as well as virtually all other Russian automakers, have been reoriented towards partnership with Chinese companies. This process, which I called a road to nowhere back in spring, is becoming even more unpromising after the imposition of the sanctions. The two main reasons for this are as follows:

Not a single car model nowadays is made of components with production concentrated exclusively in one country. This necessitates the organisation of supplies of missing components from other countries and international transactions with counterparties. Given the nature of the SDN sanctions, the manufacturers of original car components and spare parts that cooperate with AvtoVAZ, including current suppliers from China, are now bearing a sharply increased risk of sanctions when making financial transactions with AvtoVAZ and will probably be forced to abandon their existing partnerships with it.

In order to resume production of Lada-branded cars at some of its facilities, AvtoVAZ has commenced cooperation with major Chinese carmakers Dongfeng and Chery, and has already started assembly of the X-Cross 5 model at its St. Petersburg plant. The main difference between this model and FAW produced by the Chinese company (Bestune T7 model) is the logo (and, as AvtoVAZ’s CEO stated, the FAW emblem had to be kept on the steering wheel to speed up the entry of this model into the Russian market). Since AvtoVAZ is now included in the SDN list, any cooperating Chinese car company gets on OFAC’s radar and risks, at the very least, losing its business in global markets. Indeed, those companies have quite a lot to lose: Chery sells almost 500,000 cars outside China every year, FAW sells at least 400,000 cars, Dongfeng sells about 250,000 cars, and all of them are deeply integrated in global supply chains with billions of dollars worth of financial transactions. This kind of performance may become impossible if these companies fall under secondary sanctions.

One can say with certainty that the inclusion of AvtoVAZ in the SDN list prevents even Chinese companies from cooperating with this carmaker, while foreign supplies of car components for AvtoVAZ will be carried out only through ‘grey’ schemes via a myriad of various intermediaries and will entail significant transaction costs and other expenses.

The drama of Moskvich, Sollers and… JAC

Another Russian carmaker, Moskvich, was also included in the SDN list in addition to AvtoVAZ. Until 2022, Moskvich was owned by Renault, and was first called Avtoframos, and then Renault Russia. It has had a long and successful history of development in Moscow: since its foundation in 1998 on the basis of the old Soviet car plant, thanks to multi-billion dollar investments, the plant modernised its production facilities, reconstructed the manufacturing areas, robotised key operations, trained its staff and gradually localised key Renault models (Logan, Sandero, Duster, Captur and Arkana), and also assembled the Nissan Terrano. The plant’s capacity was designed to manufacture around 200,000 cars a year, and it produced 30 cars per hour in the most successful years.

Shortly after Renault suspended its business activities in Russia due to the war in Ukraine and subsequently transferred its stake in the plant to the Moscow City Government, serial production of JAC cars under the Moskvich brand was launched in November 2022, and about 30,000 such cars have been assembled since then (the Moskvich 3 model is a JAC JS4, or JAC iEVS4 in the case of the electric version, while Moskvich 6 is an analogue of the JAC Sehol A5 Plus). At the same time, the production of these models is based on the semi-knock-down or ‘screwdriver-based’ assembly technology, which, among other things, implies the possibility for the Chinese company to promptly curtail its assembly operations and stop supplying Moscow with finished car kits without incurring significant losses.

It is noteworthy that along with Moskvich, the updated SDN list now includes Sollers, i.e. another JAC partner. Its facilities in 2022 in Elabuga, where Ford Transit vans were previously produced, began assembling the JAC Sunray (light commercial vehicles) under the Sollers Atlant brand, as well as the JAC N25/35 van under the Sollers Argo brand. Moreover, this year Sollers launched the assembly of JAC T6 pickup trucks under the Sollers ST6 brand at its site in Vladivostok, where Mazda cars were previously produced. In addition, JAC remains in partnership with Russia’s largest truck manufacturer Kamaz, which was entered in the SDN list back in June 2022 and which, a little earlier, had launched the production of medium-duty trucks from the Compass family, based on the JAC N-series model.

Therefore, after the adoption of the latest package of U.S. blocking sanctions, JAC becomes the only Chinese automotive company that simultaneously cooperates with three Russian carmakers from the SDN list. Perhaps JAC’s interest in doing business in Russia stems from the company’s very disappointing performance in its home market (JAC’s passenger car sales in China shrank almost 10 times between 2016 and 2021, and its market share in 2021 was 0.16%), but nevertheless, if the ‘outsider of the Chinese car industry’ falls under secondary sanctions, this will be devastating for its business, even despite the very modest internationalisation of its operations (JAC cars are mainly exported to Latin America) and attempts by its Russian partners to sanction-proof the relationships by using alternative component supply channels and financial settlement mechanisms.

It should be emphasised that the extension of U.S. sanctions onto new players from the Russian automotive industry objectively reduces the interest of Chinese companies in developing partnerships with Russian car manufacturers. Shortly after Kamaz was added to the SDN list, the Weichai Diesel Engine Corporation stopped supplying gas engines to the Kamaz plants in Naberezhnye Chelny and Neftekamsk, and the joint venture between the two companies, Kamaz Weichai, was renamed Volga Industrial Engines, with Weichai withdrawing from the group of its founders altogether. Such cases, as well as the example of JAC, which is now under OFAC’s scrutiny, are likely to make such brands as BAIC, Kaiyi, SWM, JMC and Foton reconsider the risks of cooperation and business development with Avtotor, a Kaliningrad-based car holding company that was not included in the updated SDN list, while Chery, for example, might begin to think about an action plan in case the SDN list is extended further to include the former Volkswagen plant in Kaluga, which was taken over by the Avilon car dealer and which Chery still contemplates as a location to assemble its cars in Russia.

Russian carmakers in the SDN list

By including the largest Russian carmakers in the SDN list, the United States has sent a very clear signal to China that "saving the drowning man is up to the drowning man" and that it is economically unreasonable to risk a global car market of many millions of cars for the sake of a presence in the Russian market with an expected volume of about 1 million cars, even though the total profit of the seven major Chinese car companies in Russia at the end of 2022 rose to a record level of 79 billion roubles (and was comparable to the total profit of the Germans and Koreans for the whole of 2021).

Today, the USA and the EU are already actively developing the practice of secondary sanctions against foreign companies from third countries (mainly all kinds of intermediaries) involved in circumventing the existing restrictions and supplying sanctioned goods to Russia. There is every reason to believe that this practice will soon be supplemented by imposing sanctions on companies that act as partners of sanctioned persons from Russia, and the new restrictive measures will primarily target Chinese car manufacturers.

All this undermines the appeal of the Russian automotive industry for Chinese players, reduces the possibility for Russian car manufacturers to participate in global supply chains, increases the costs of imports through unofficial channels and ‘grey schemes’, curtails exports, etc. Apparently, the further development trajectory of the automotive industry will follow the Iranian scenario: there will be several large car manufacturers operating in the country, working only for the domestic market; the companies will have no access to the latest technologies used by the global automotive industry and severely limited opportunities to import original car components and spare parts for their own needs; the cars produced by the industry will be significantly inferior to foreign cars in terms of quality, safety, technology and comfort; the industry will become gradually ‘simplified’, experiencing a constant shortage of investment, partially compensated by government’s cash injections from the central budget. Such a scenario does not bode well for Moskvich, for example, due to the excessive budget dependence of this enterprise. Not a city-forming enterprise, Moskvich occupies areas within Moscow’s third transport ring that are very attractive for land development companies, which probably dooms Moskvich to repeat the sad fate of another Moscow automobile plant, ZIL, whose industrial territory was reorganised and is now being actively built up with commercial and residential real property.

It is noteworthy that one of the goals of the strategy recently adopted by the Russian government for the development of the automotive industry until 2035 is to ensure the technological sovereignty of the industry. Given the current trends and the nature of the restrictive measures imposed on the country’s automotive industry, the government has every chance of achieving this goal much sooner than the stated date. However, this will lead to ever more ‘Iranian oddities’ on Russian roads, where, even if dozens of cars collide, not a single airbag will be inflated in any of them.

Opinion

COMMENT: Hungary’s investment slump shows signs of bottoming, but EU tensions still cast a long shadow

Hungary’s economy has fallen behind its Central European peers in recent years, and the root of this underperformance lies in a sharp and protracted collapse in investment. But a possible change of government next year could change things.

IMF: Global economic outlook shows modest change amid policy shifts and complex forces

Dialing down uncertainty, reducing vulnerabilities, and investing in innovation can help deliver durable economic gains.

COMMENT: China’s new export controls are narrower than first appears

A closer inspection suggests that the scope of China’s new controls on rare earths is narrower than many had initially feared. But they still give officials plenty of leverage over global supply chains, according to Capital Economics.

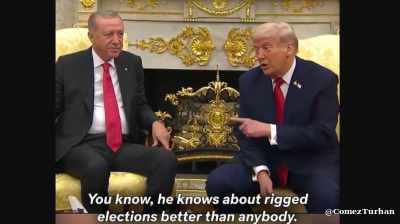

BEYOND THE BOSPORUS: Consumed by the Donald Trump Gaza Show? You’d do well to remember the Erdogan Episode

Nature of Turkey-US relations has become transparent under an American president who doesn’t deign to care what people think.

_2_1761012864.jpg)