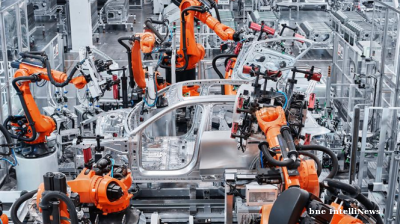

As Russia’s economy slowly comes under more pressure as the military Keynesianism effects that have been boosting growth start to wear off, Russia’s leading firms are casting around for ways to enhance productivity. Many are increasingly turning to automation and artificial intelligence (AI) solutions. However, concerns about unemployment. the lack of access to high-tech thanks to sanctions and the growing difficulties with imports are creating headaches that are holding development back.

The Kremlin has always been nervous about automation and robots, as part of Russian President Vladimir Putin’s social contract with his people is to provide work and improve their pay.

The use of robotics or AI comes with fears of job losses amongst workers which have resisted the automaton of factories, reports Vedomosti.

For the moment those fears are overstated. With unemployment at an all-time low of 2.4%, Russia is suffering from a chronic labour shortage and cannot fill all the existing workplaces. For now, companies are looking to technology to simply boost the productivity of existing workers.

Several companies surveyed by Vedomosti are already incorporating digital tools to improve efficiency. A representative of steel major Severstal said that the company is focusing on robotics and automation to boost productivity. However, for sustainable implementation, it is crucial to develop the necessary staff competencies and identify which inefficient processes should be automated. The company plans to first eliminate losses through lean production technologies before defining staff roles and responsibilities, and finally setting clear technical specifications. As part of its productivity drive, Severstal aims to reduce end-to-end costs, using various tools to track productivity trends and benchmark against peers. While the company saw a 12% rise in sales productivity per worker during the first half of 2024, physical output dropped slightly due to reduced steel production during a blast furnace overhaul.

At the Binnofarm Group, a top two pharmaceuticals firm, the company’s focus on automating parts of its technological and production processes. At its Kurgan plant, for instance, AI-based computer vision is used to detect defects in medicine bottles, cutting costs and reducing human error.

Leading telecom operator MTS is also ramping up automation. The company plans to automate approximately 9mn man-hours in 2024, with many divisions already deploying Robotic Process Automation (RPA) to cut labour costs. MTS call centres are increasingly relying on voice and chatbots, further reducing the need for human operators.

Challenges remain

But many obstacles remain. Digitalisation and AI rely heavily on data, but collecting the data remains a problem as the machinery at many plants, especially in heavy industry, were installed in the Soviet-era and data collection facilities is extremely difficult to add to a machine made in the 1950s. The entire production line would have to be updated to introduce digital or AI management systems to control it in some cases.

Russia also lacks sophisticated machinery as it has missed out on two generations of revolutions in precision tools revolutions. That has made Russian firms almost entire dependent on imports in some sectors like gas turbines, which used to all be supplied by Siemens.

Overall, the Western technology sanctions have largely failed to cut Russia off entirely from Western technology, but nevertheless the headaches have put real constraints on factories wishing to modernise and boost productivity using modern technology.

Much of Russia’s industrial equipment dates back to the 1950s, making data collection and digitisation difficult without upgrading entire production lines.

Russia is still a long way away from German or Japanese fully robotic production and with average wages on the order of $725 a month, labour costs are still not the defining factor.

But the biggest obstacle firms face is the high cost of technological re-equipment. Over the past two years, many businesses have modernised their operations using preferential loans and state support, reports Vedomosti. But after the Central Bank’s introduced its tightening policies in the first quarter of last year, the prime interest rates have climbed to a crushing 19% and the Central Bank of Russia (CBR) is expected to hike again to 20% at the next monetary policy meeting. Inflation may have peaked at 9% in August, but inflation pressures caused by the war in Ukraine remain high and there is no prospect for easing monetary policy starting until next year. The cost of borrowing is such that the CBR estimates that companies are spending one ruble in four on interest payments. Those costs of borrowing are slowing the pace of investment in modernisation, with only major exporters remaining relatively unaffected.

Globally, Asia leads in industrial robot adoption, driven primarily by countries like China, Japan and South Korea. According to the International Federation of Robotics (IFR), China has become the largest market for industrial robots, accounting for around 44% of global robot installations in 2021. The robot density in China, measured as the number of robots per 10,000 manufacturing workers, has surpassed 300, whereas South Korea continues to have the highest robot density at 932 robots per 10,000 employees.

Europe also has high levels of robot adoption, with Germany leading the way. Germany's robot density was about 371 robots per 10,000 employees in 2021, particularly in the automotive and electronics sectors. The United States follows with a robot density of 274 robots per 10,000 employees.

Russia trails badly behind with a robot density of a mere 6 robots per 10,000 employees in the manufacturing sector, according to reports, far below the global average of 141 robots per 10,000 workers.

Currently the isolated examples of robotisation are not enough to transform the economy or significantly boost national productivity. Yet with the pressures of sanctions and a sharp slowdown expected in 2025, Russian firms need to boost productivity if they are to avoid stagnation or damaging their competitiveness. Innovation is also hampered by cheap labour, limited competition, state protectionism and a poor investment climate.

Russia has a better chance to participate and benefit from the AI revolution, as software engineering remains one of its strongest suits, and the Kremlin is positioning itself to become a major player.

The Russian government has set ambitious goals for AI development, with initiatives aiming to foster AI research, innovation and adoption across various industries. In 2019, Russia released its National AI Strategy, which lays out a plan to become a top-five AI power by 2030. This strategy focuses on increasing AI investments, fostering talent and integrating AI into key sectors such as defence, agriculture, healthcare and transportation. Key government players, such as the Russian Ministry of Defence and Sberbank, have invested significantly in AI research and infrastructure.

Russia has a strong base of academic research in AI, with institutions like Skolkovo Institute of Science and Technology and Moscow Institute of Physics and Technology making advances in machine learning, neural networks and data analysis. Russian scientists are well-regarded for their theoretical work, particularly in areas like cybersecurity and AI algorithms.

However, the brain drain remains a problem with the very best talent being poached by better paying international companies that can also offer a more fruitful research environment, particularly in the US and Western Europe. Russia is investing in talent retention through domestic AI development programmes and partnerships between academic institutions and industry.

But the AI sector in Russia remains narrow and shallow, with a lack of venture capital. The progress and investment into AI is very concentrated into the big players such as the state-owned retail banking giant Sberbank and Yandex, the internet giant, which are amongst the two most active players, outside the military sector.

Tech

China increasing its lead in robot technology use

China is consolidating its dominance in the global industrial robotics market, accounting for 41% of the world’s operational robot stock and more than half of all new installations in 2024, according to the International Federation of Robots.

The Iranian inventor that invented the floating shoes, has now built a propeller-less propulsion system ideal for flying taxis

Mohsen Bahmani is an Iranian-born mechanical engineer and a man with a dream. When he was just 17 years old, he made a pair of floating shoes that allow you to walk on water. Now he has built a propulsion system ideal for flying taxis.

_(1).jpg)

OpenAI to invest up to $25bn in Argentina under Milei incentive scheme

Artificial intelligence giant OpenAI and energy company Sur Energy have signed a letter of intent to develop a data centre hub in Argentina requiring investment of up to $25bn.

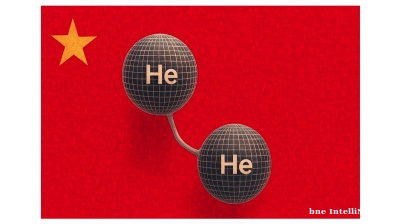

Helium was China's rare earth metals Achilles' heel

China has a devastating tool in its escalating trade war with the US: rare earth metals (REMs). Last week, Beijing announced new restrictive export controls on the export of anything with even a smidgen of Chinese-produced REMs.

_1760544574.jpg)