In June 2021, Volkswagen was Russia’s fifth most popular car brand. It was selling tens of thousands of new vehicles a month, and the future looked rosy. Fast forward a year, and reports are emerging that the German auto giant intends to sell its car assembly plant in the western Russian town of Kaluga.

Along with most other major carmakers, Volkswagen announced that production at its Russian sites would be suspended in March 2022. Western sanctions imposed following the invasion of Ukraine slammed the brakes on Russian car production, depriving manufacturers of the tools and materials needed on the production line.

By May, only two of Russia’s 20 car plants were still working, and even they were operating at dramatically reduced capacity. Satellite images of the new car lot behind the Ford plant in St Petersburg showed it to be completely empty in July.

If the reports are true, Volkswagen will be following in the footsteps of a host of other Western carmakers who have decided that the difficulty of sourcing parts combined with dwindling domestic demand and the reputational damage of continuing business as normal has made operating in Russia unfeasible. Sources cited by Reuters say that Kazakhstan’s Asia Auto could take over Volkswagen’s Kaluga plant, which employs around 4,200 workers.

Spoke and wheel

The potential sale by Volkswagen is a symbolic moment for Russia’s car industry, but it comes as little surprise to industry experts. It is the consequence of a systemic vulnerability in the Russian model of car manufacturing, which makes the country largely dependent on Western technology to build its vehicles.

Following the collapse of the Soviet Union in 1991, Russia’s automobile industry accepted a high degree of dependence on Western technology and supply chains in order to provide a steady flow of modern vehicles to Russia’s domestic market. This made sense in the short term, addressing the immediate problems of outmoded car-manufacturing infrastructure left over from Soviet times and widespread corruption in procurement and manufacturing.

In the longer term, however, the decision to integrate with Western manufacturers was not consistent with Putin’s aim to build what commentators called “fortress Russia” – an almost autonomous economy which could draw on vast reserves and domestic products to weather sanctions. The trade-off in car making was successful in the short term, keeping the nascent Russia well supplied with new vehicles, but left the auto industry uniquely exposed to sanctions risks from 2014 onwards.

In other industries, the latent pre-war imports still working their way through the system, or the availability of domestic alternatives has meant that the effect of sanctions has not yet become visible in output figures or prices.

Cars, on the other hand, tend to rely on a nimble supply chain, with high-technology components often imported from Europe or America and assembled quickly near to their end market. This “just-in-time” production strategy means that inventories tend to run on narrow margins, which explains why part shortages stopped car manufacturing so quickly after the imposition of sanctions.

The result has been a sudden and dramatic drop in both the demand and production of cars. With specialist components like computers, semiconductors and catalysts harder to source, the price of cars has soared, and consumers have responded by buying less. New car sales in Russia were down by 82% in June 2022 compared to the same month last year, with Russia’s 25 largest car brands all posting a year-on-year drop in sales. (chart)

“The dramatic demand collapse is driven by rising prices, low consumer confidence and uncertainty surrounding the future servicing of vehicles,” explained Sergey Suverov, a strategist at Russian investment fund Aricapital. “The current fleet of new Western cars and trucks will last about 3-4 years before real big problems start showing up, stopping deliveries and safe driving.”

Russia’s most popular cars, however, are not foreign – they are Soviet classics which have been re-vamped for the twenty-first century. The subcompact Lada Granta was Russia’s highest selling car model in June 2022, followed by the Lada Vesta. But even they were made with the help of Western carmakers until the war intervened.

Ladas are produced by Russia’s largest carmaker AvtoVaz, which was until recently majority owned by France’s Renault. In his article The Great Escape, Professor Thane Gustafson explains how the notorious former Renault CEO Carlos Ghosn contributed to the digital revolution of cars in Russia by bringing the “spoke and wheel” model of manufacturing to AvtoVaz. High-tech components were made in France and shipped to AvtoVaz plants for assembly using cheaper Russian labour.

In 2009, Ghosn was boasting that Russia would soon be Renault’s largest market as he prepared to increase his stake in AvtoVaz.

But production at AvtoVaz was paralysed by sanctions after the war started, with all the manufacturer’s staff released on vacation from April 4-24 2022. Renault sold its stake in the carmaker to NAMI state automotive engineering institute in April, reportedly for the symbolic price of one ruble. As part of the deal, it retained the right to buy back its Russian assets within six years.

Going offroad

Meanwhile, Russia is keen to show that AvtoVaz and other carmakers can cope just fine without the Western components they got accustomed to ordering.

In an attempt to jump-start the car market, authorities relaxed safety standards in May, scrapping the requirement for airbags, seatbelt pretensioners, and anti-lock braking systems (ABS) and lowering emissions standards.

When it re-started production of its popular Granta model in June, Lada offered only manual transmission, and a host of digital components were missing, including the electronic stability control system. Until late July, new Lada cars were reportedly missing air-conditioning systems.

When news broke that Renault was leaving Russia, speculation about the future of AvtoVaz was rife. The company’s flagship complex in Togliatti employs over 32,000 workers, who have all been on a four-day working week since April due to shortages of components.

Moscow Mayor Sergei Sobyanin trumpeted Renault’s handover of AvtoVAZ as a triumph for the workers, suggesting that it would protect Russian jobs. Renault Group CEO Luca de Meo emphasised the same thing, insisting that “we are making a responsible choice towards our 45,000 employees in Russia.”

Russia’s car industry employs around 1% of the country’s workforce, and hundreds of thousands of jobs are at risk due to the slowdown. When a contingent of workers from Russia’s iconic truck builder GAZ drove to Germany to raise awareness of the risks sanctions pose to Russian jobs, the chairman of the company’s Workers’ Council told bne IntelliNews that “If you include the families of the workers then the knock-on effects will impact the whole population of Nizhny Novgorod.”

Nizhny Novgorod is one of Russia’s largest industrial towns. It is not the only place dependent on car manufacturing, though. Nearby Togliatti and Izhevsk are also vulnerable, with big plants in both cities.

Further west, the town of Kaluga boasts three plants, where Volkswagens, Volvos and Peugeots are made. Peugeot may soon open its assembly plant up to other carmakers in order to reduce costs.

The St Petersburg area also has a cluster of car plants, most notably the Hyundai plant, the second largest in the country. Other facilities are scattered across Russia, including Vladivostok, Kaliningrad, and Yaroslavl.

Some towns, such as Nizhny Novgorod and Izhevsk, boast a host of other industrial producers, so their local populations are less exposed to the risk of job losses.

In an attempt to stir up patriotic demand, Moscow’s mayor Sergei Sobyanin announced plans to re-launch the popular Soviet brand “Moskvitch” (Muscovite) at AvtoVaz. The Russian government apparently hoped to secure the support of Chinese state-owned carmaker Anhui Jianghuai Automobile Co. (JAC) to provide parts and designs for the new Moskvitch models, but there have been no signs that it was successful in this endeavour. According to reports, no designer has been engaged and at the end of July the Financial Times reported that Chinese investment into Russia has fallen to zero.

However, AvtoVaz has successfully revived the classic three-door Lada Niva Legend, which is now priced at $13,600.

AvtoVaz CEO and former minister of transportation Maxim Sokolov, who has vowed that 95% of the Lada Niva’s components will eventually be domestically manufactured, said: “Production resumption of the second Lada model and the launch of another assembly line in the current difficult conditions is a real victory for the entire AvtoVaz team … The company is going on to make every effort to resume production of all cars of the Lada line-up, actively working with suppliers from Russia and friendly countries.”

Reduced visibility ahead

For all the triumphalist rhetoric, though, it is unclear how much longer Russia’s car industry can stagger on with a critical shortage of foreign-supplied parts, which it depends on for at least 50% of its manufacturing.

Decoupling has never been more important. Russia’s automotive industry employs 300,000 people and 3mln more work in related industries. But in July 2022, over 120,000 unsold cars had piled up in dealerships due to high prices and collapsing demand.

“The prospects are unclear. Production will degrade a lot, as many critical components (engines and their parts, transmissions, control units, high-precision metal parts) are gone and no replacement is in sight. This translates into smaller volumes and a return to 30-year-old technologies with higher costs per unit,” explained Suverov.

The US tightened its export controls in May, banning the sale of an extra 200 products to Russia and bringing its sanctions regime into better alignment with the EU’s existing measures. New items added to the sanctions list include catalysts, boring tools, reaction engines, motors, pumps and machines for finishing metal.

Russia’s government has promised to accelerate its programme of import substitution. But it will take years of research and huge investments in domestic production before Russian carmakers will be able to produce modern cars with digital components sourced exclusively from within Russia. Western sanctions have made parallel imports harder to find, even from manufacturers in non-Western countries who are reluctant to risk financial penalties.

“Import substitution can cover only a limited number of relatively low-tech components, (simple plastic parts and mechanisms). Some components can be made with the help of reverse engineering (the Ministry of Industry and Trade is already financing this),” Suverov explained.

“Any parts substituted will suffer from lower quality and higher price (this double threat had been a big problem even before the sanctions, now it will get worse). Most likely, part of the solution will be grey and black import of components from other countries branded as Russian,” he added.

New car sales data serve as a predictor of consumer sentiment. Due to their high value, cars and other big-ticket items are often the first to register declining demand.

In its most recent figures, the Bank of Russia expects a GDP contraction of between 4-6% in 2022, followed by further contraction in 2023. Other analysts are making still bleaker forecasts. The road ahead looks rocky for Russia.

Features

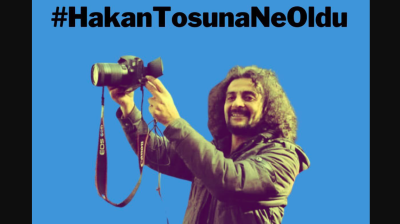

Journalist beaten to death in Istanbul as security conditions in Turkey rapidly deteriorate

Publisher, meanwhile, is shot in leg. Reporters regularly experience violence, judicial harassment and media lynching.

Agentic AI becomes South Korea’s next big tech battleground

As countries race to define their roles in the AI era, South Korea's tech giants are now embracing “agentic AI”, a next-generation form of AI that acts autonomously to complete goals, not just respond to commands.

Iran's capital Tehran showcases new "Virgin Mary" Metro station

Tehran's new Maryam metro station honours Virgin Mary with architecture blending Armenian and Iranian design elements in new push by Islamic Republic

Indonesia’s $80bn giant seawall

Indonesia’s ambition to build a colossal seawall along the northern coastline of Java has ignited both hope and heated debate. Valued at around $80bn, the project aims to safeguard the island’s coastal cities from tidal floods and erosion.