Some prominent figures in the international fashion and beauty industry were optimistically forecasting a new “roaring twenties” and an explosion in consumption even as most of Europe went back into lockdown earlier this year. For Albania’s garment manufacturing industry, which supplies famous brands in Italy and elsewhere, this is a far off dream. With orders still sluggish, for now it’s a question of slowly stitching back together an industry devastated by the pandemic.

As in other sectors like car manufacturing and electronics, which also have complex international supply chains, the clothing and textiles sector suffered sudden demand and supply side shocks in the early months of 2020. The initial disruptions to supplies from China, followed by factory shutdowns in Europe and elsewhere as the pandemic spread around the world, was accompanied by a slump in demand as people stopped going out — and to a large extent stopped buying new clothes — during the spring 2020 lockdowns.

The burden fell especially hard on companies and their employees in lower income countries — among them Albania — supplying western markets.

The textile and footwear sector is the single largest category in Albania’s exports; in 2019 exports in this category amounted to ALL118bn, 40% of the ALL299bn of goods exported during the year. Of that total, ALL92bn — almost a third of all exports — was textile and footwear products exported to Italy.

Albania’s strength in this area dates back to the communist era, when textile production and garment manufacturing was one of the most important sectors of the economy, with state factories supplying the local population and producing for export. The Kombinat Stalin Textile Mill in the outskirts of Tirana employed over 2,000 people in its heyday. Today, Albania is no longer a major textile producer, and its factories, now privately owned, many of them by Italian businesspeople, import materials that are then turned into partially or fully finished garments or shoes then re-exported. Data on this industry, dubbed ‘facon’, is incomplete, but Albania is estimated to have around 1,000 companies engaged in garment manufacturing, employing up to 90,000 people.

Aside from Albania’s previous history in the sector, the ‘facon’ industry developed thanks to Albania’s low costs — this is a labour-intensive sector and Albania has the lowest minimum wage in Europe — and its proximity to Italy, one of the world’s fashion capitals. Italy, just across the Adriatic Sea from Albania, has a large Albanian diaspora and is the country’s top trading partner. Typically, clothes and shoes are exported almost complete to Italy, where Italian workers add the final touches and packaging, allowing the products to go out to the shops with the prestigious ‘Made in Italy’ label.

In just one example, Kler, a major Albanian CMT (cut, make and trim) company located on the highway between Albania’s capital Tirana and the port city of Durres, supplies high-end men’s shirts for Italian brands including Brancaccio C., Alex Doriani and Cristiana C. Kler’s website says the company “prides itself on its high quality make, quick turn-around capacity, convenient location to EU fabric markets [and] competitive pricing with a low cost of labour.”

The pandemic strikes

When the pandemic started, it had a quick and extremely damaging impact on companies and workers in producing countries around the world, where many manufacturers already struggled with cash flow and operated on extremely tight margins. As early as March 2020, the Clean Clothes Campaign warned that companies were closing in Albania and elsewhere because of the shortage of raw materials from China combined with declining consumer demand and shop closures, which resulted in major international retailers cancelling orders (including some already completed) and demanding discounts on orders already shipped.

Rights activists around the world focussed on the clothing industry warned that the financial burden of the pandemic was being passed on to the most vulnerable people in the industry, namely workers in low-income countries, many of whose employers were unable to pay them for work already done. A report from the Centre for Global Workers Rights (CGWR) and the Worker Rights Consortium (WRC) said that fashion companies from the US and Europe cancelled or refused to pay for $16.2bn of orders in April-June 2020, resulting in textile workers losing $1.6bn in wages. During this period, fashion companies in the EU took delivery of garments worth 45% or $6.5bn less than in the same period of the previous year. In the US this figure dropped by around one half or $9.7bn.

Workers in Albania’s garment sector — around 95% female with an average age of 31-35 — were already in a precarious situation where they faced multiple labour rights abuses and job security dependent on their factories securing fresh orders. This immediately worsened when COVID-19 started spreading across Europe.

The International Labour Organization (ILO) reported the “immense impact” of the pandemic on the textiles, clothing, leather and footwear industries. “Quarantine measures, closure of retail stores, illness and salary reductions have suppressed consumer demand. At the same time, this sector is struggling with severe supply-side disruption; as workers are told to stay at home, supply chains grind to a halt and factories close. Women in Albania’s apparel and footwear sector are among the hardest hit by the economic woes associated with the COVID-19 health crisis,” said an ILO report.

“When the pandemic started it was very difficult and nobody knew what to do. In Albania everything was blocked. All the companies and schools were closed,” said Mirela Arqimandriti, executive director of the Gender Alliance for Development Centre (GADC) in Tirana, which has been working with women and girls in Albania’s garment sector for the last five years. Surveys by the GADC show many of the women working in the garment industry are the breadwinners in their households, with their husbands, for example, picking up daily work in construction or seasonal work abroad. Many have more than two children and are also responsible for elderly family members.

The Albania government shut factories down in the initial lockdown in March 2020, but those in the garment industry were the first to reopen after factory owners put pressure on the government to allow them to continue working. According to Arqimandriti, the women who went back to work “were first to be infected, massively”, as factories became hotspots for the spread of COVID-19. Even when in the factories that followed government guidelines on disinfection and distributed masks and hand sanitiser to their workers, the virus continued to spread; the piecework carried out in many factories made social distancing virtually impossible.

“There is some distancing in factories, but women can suffer from the lack of proper distancing for example on transportation to and from their workplaces or because there are typically only one or two bathrooms at each factory,” said Eneida Mjeshtri of the Centre for Labour Rights in Tirana.

Looking at the financial impact on workers, Arqimandriti said that when factories reopened many were operating at a low capacity, offering their workers only a few hours a day, with their pay adjusted accordingly. Others were unable to come to work as closed schools meant they had young children at home, or without public transport they couldn’t get to their workplaces. While the government extended support for workers forced to stay at home by the pandemic, there were cases of factors laying off workers as demand shrank, and once they were removed from the payroll they were unable to access support.

According to a Reuters report, the Albanian government gave a one-off payment of ALL40,000 to 179,000 workers after 50,000 lost their jobs, including in the garment sector, and approved sovereign guarantees to help pay employees. However, industry insiders told the newswire that most companies failed to secure bank loans despite the guarantee.

By June 2020, 50,000 people from across the Albanian economy had been removed from the payroll and declared unemployed. While some were later taken back as factories reopened, Arqimandriti says that there is little information about the current situation. Some companies entered bankruptcy, while others struggled to access support from the government channeled through local banks.

Even before the pandemic, conditions weren’t very good, Arqimandriti and Eneida both say that while Albania has a good labour code, based on EU law, it is poorly enforced and officials have insufficient resources to monitor the industry effectively. On top of the low wages and long hours in the sector — workers are rarely compensated for overtime — there are also reports of other abuses such as poorly enforced health and safety standards and sexual harassment.

A 2016 report from the NGOs Clean Clothes Campaign, Change Your Shoes, Berne Declaration and ENS shows the situation is similar in garment factories across several Central and Southeast European countries. “Labour on a Shoestring: The Realities of Working in Europe’s Shoe Manufacturing Peripheries in Albania, Bosnia-Herzegovina, Macedonia, Poland, Romania and Slovakia” says that "problematic working conditions and very low wages in particular, are occurring endemically across global supply chains worldwide”, with being based in Europe not a guarantee of good working conditions. On the contrary, “In Europe’s low-wage countries, the clothing and shoe industry is notorious for poor pay and bad conditions."

From fashion to PPE

One way that companies have managed to survive the criss is by switching from fashion apparel to production of face masks and other personal protective equipment (PPE), though this was not in sufficient volume to come close to making up for the shortfall in fashion orders for the industry as a whole.

German international development agency Deutsche Gesellschaft für Internationale Zusammenarbeit (GIZ) GmbH supported the tailoring industry in Albania during the pandemic. "The shutdown of the fashion industry in Italy and other European countries reduced the demand for textiles “made in Albania” immensely. According to our own studies, in 2020 alone, the potential loss of the sector summed up to €180mn,” a GIZ spokesperson told bne IntelliNews. “In April 2020 GIZ started to support local garment companies by giving advise on how to certify their production lines for personal protective equipment. Given the high demand in Germany, starting the production of PPE kept these companies running.”

GIZ advised the producing companies on ensuring the quality standards for protective wear, and also initiated cooperation between Albanian and German companies through its networks with chambers of commerce in the two countries. Among the Albanian companies it has supported are EfaSolutions, which produced hundreds of thousands of gowns since June 2020, that were sold to customers in Germany. “EfaSolutions even subcontracted four other local textile companies to satisfy the high demand for PPE. This helped secure nearly 600 jobs and create 400 new jobs in the textile sector, which has still not yet recovered from the crisis. Alongside their clothing, Efa Solutions still manufactures protective gear despite the decreasing demand for PPE, as they have built a productive system which ensures quality of high international standards,” the spokesperson said.

Back to the shops

In the last few months restrictions have been fully or almost fully lifted in many parts of Europe and North America, allowing people to return to workplaces, start socialising and attending events again, go on holiday and get back to the shops. Data from the British Retail Consortium, for example, showed the fastest quarterly growth in retail sales on record in the second quarter of 2021. Germany’s retail sales saw a faster-than-expected rise in June as restrictions were lifted, while Italy’s retail sales returned to growth in the month.

It’s a little early to tell whether the pandemic will have had a lasting impact on shopping habits. Under lockdown people abandoned such constricting garments as tailored trousers, jackets and bras (another popular made in Albania item) in favour of joggers and sweatshirts, if they bothered to change out of their pyjamas at all. Some analysts and industry insiders believe the enforced saving during the lockdowns in 2020 and 2021 will have led people to reassess their relationship with fast fashion in particular and move away from over-consumption towards more measured and environmentally conscious purchasing. Consultancy McKinsey expects in its report “The State of Fashion 2021: In search of promise in perilous times” retail sales in Europe and the US to remain a few percent below the 2019 level this year, and for only a modest recovery in 2022.

Others have forecast that after months shut up at home people are already embarking on a frenzy of “revenge consumption” that will fuel the post-COVID recovery, with some even comparing the 2020s to come with the “roaring” 1920s that followed WW1 and the 1918 flu pandemic. On a call with analysts, L’Oréal CEO Jean-Paul Agon forecast: “When the COVID [is] gone, people will be happy to go out again, to celebrate, to socialise and this will be like in the famous Roaring ‘20s … This will be the fiesta of makeup and fragrances.”

Another consequence of the pandemic — potentially a positive one for Albania — is that supply chain disruptions, such as those between East and South Asian suppliers and European markets, have caused companies to rethink their supply chains to make them more resilient to such disruptions in future. One of the ways to do this is by ‘nearshoring’ production and Albania, along with the other Western Balkans countries, and other relatively low-income European countries like Moldova and Ukraine, are well placed to do this.

Features

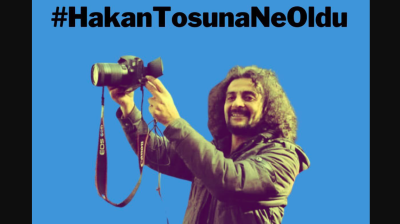

Journalist beaten to death in Istanbul as security conditions in Turkey rapidly deteriorate

Publisher, meanwhile, is shot in leg. Reporters regularly experience violence, judicial harassment and media lynching.

Agentic AI becomes South Korea’s next big tech battleground

As countries race to define their roles in the AI era, South Korea's tech giants are now embracing “agentic AI”, a next-generation form of AI that acts autonomously to complete goals, not just respond to commands.

Iran's capital Tehran showcases new "Virgin Mary" Metro station

Tehran's new Maryam metro station honours Virgin Mary with architecture blending Armenian and Iranian design elements in new push by Islamic Republic

Indonesia’s $80bn giant seawall

Indonesia’s ambition to build a colossal seawall along the northern coastline of Java has ignited both hope and heated debate. Valued at around $80bn, the project aims to safeguard the island’s coastal cities from tidal floods and erosion.